At Tech India Engineers Pvt. Ltd. (TIEPL), we believe that great service starts with a deep understanding of our clients’ needs. That’s why Annual Maintenance Contracts (AMC) and Repair/Rate Maintenance Contracts (RMC) are designed with flexibility, transparency, and reliability at their core.

Using ERPNext, client manages all maintenance schedules, machines, and service contracts in one place. This means less hassle, better tracking, and quicker response—across all branches.

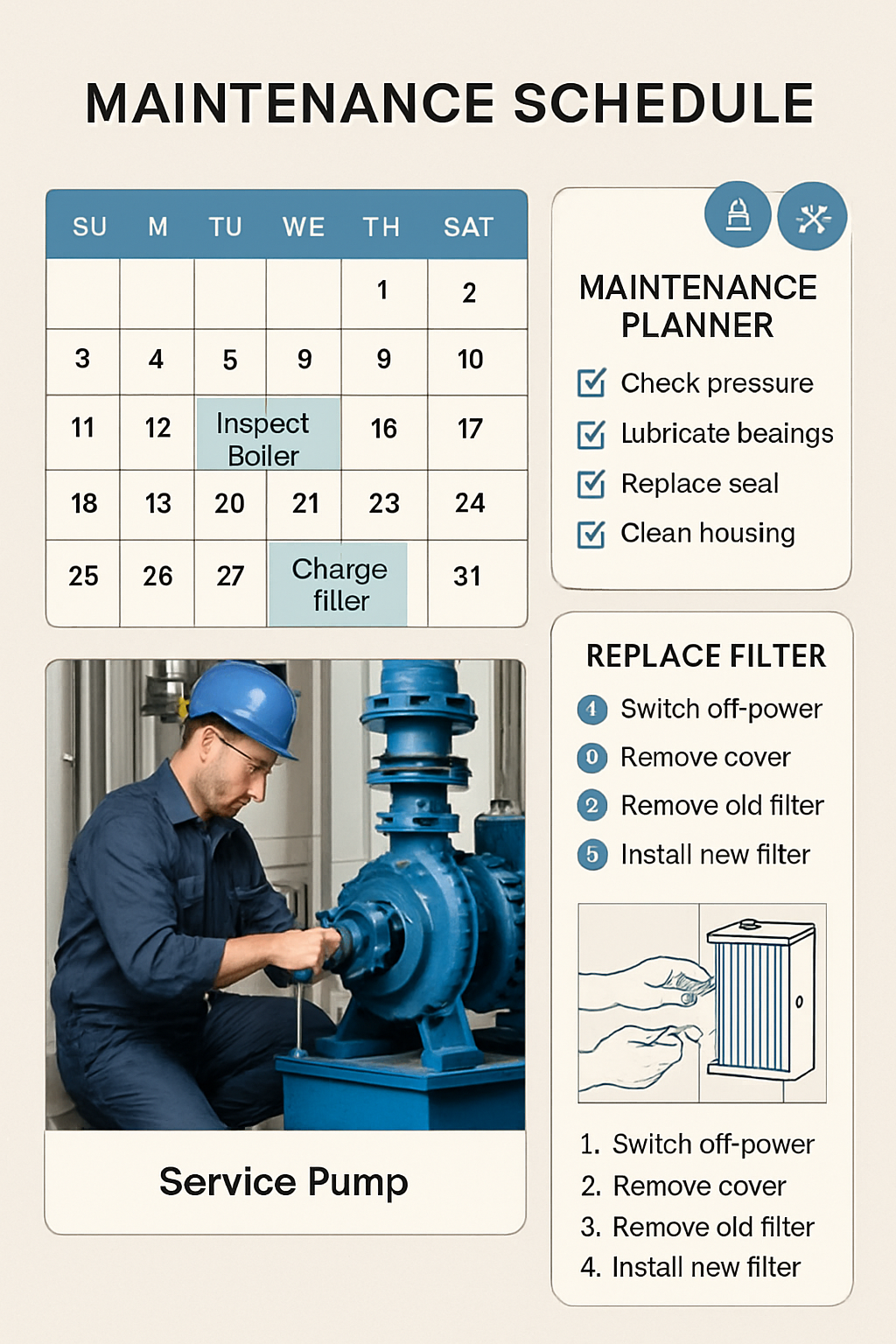

Maintenance Schedule in ERPNext

A Maintenance Schedule in ERPNext is a structured plan that outlines when and how maintenance activities should be performed on equipment, machines, or assets over a specific period.

Understanding the Two Contracts

- AMC (Annual Maintenance Contract) AMC clients enjoy predefined maintenance visits as part of a fixed agreement. Scheduling is done in advance, often for an entire year, giving clients complete visibility into upcoming service windows.

- RMC (Repair / Rate Maintenance Contract) RMC clients benefit from on-demand maintenance at agreed rates. While not scheduled as rigidly as AMC, RMC still demands timely responses and efficient planning based on equipment health and availability.

Machine Availability Check – A Smart Checklist System

Our system ensures conflict-free maintenance scheduling by checking both machine availability and activity allocation per branch. Here's how it works:

-

Each activity/item (like Thermography Test, Temperature Measurement, etc.) is assigned a specific number of machines at that branch.

-

While scheduling, the system checks if the activity has already reached its maximum machine limit for the selected date. If the limit is reached, the system shows a validation message and prevents scheduling on that date, prompting the user to select an alternative date.

Auto Notifications – Stay Informed 🔔

We keep you in the loop at every step. Once maintenance is scheduled, ERPNext ensures timely alerts so you're always prepared:

- 30 Days Before – Early notification to help you plan ahead.

- 7 Day Before – Reminder to ensure everything is ready.

These alerts are sent via email/SMS/portal notifications so your teams are always informed and can prepare accordingly.

Flexibility through Rescheduling

We understand that plans can change—and that’s perfectly okay. With ERPNext, rescheduling is quick and user-friendly:

- Simply use the “Update” button in the Schedule Table to request a new date

- All changes are logged and visible, ensuring full transparency and traceability and update the calendar without disrupting your existing schedules

Maintenance Visits in ERPNext

A Maintenance Visit in ERPNext is a service record generated against a planned Maintenance Schedule, Service Request, or direct customer call.

After Each Visit – Real-Time Updates

Once a visit is completed, the system:

- Automatically updates the schedule status

- Logs visit details, remarks and others

- Refreshes the overall contract progress

This gives you a real-time overview of every visit completed, pending, or rescheduled—essential for compliance and audit tracking.

Visual Calendar View for Better Monitoring

We provide a calendar dashboard view of predictive maintenance

Final Thoughts

Creating a maintenance schedule in ERPNext is not just about logging dates — it’s about automating service reliability, ensuring technician readiness, and keeping customers informed. Whether you manage two branches or twenty, ERPNext scales with you.

Need help setting this up? We are here to assist with tailored ERPNext implementation, Customization and support services.

No comments yet. Login to start a new discussion Start a new discussion